LDPE FILM, ABS, ENGINEERED RESINS, PC, PE, PP, PUR, PVC AND SELECTED METALS SUCH AS COPPER AND ALUMINUM.

|

current blowout specials

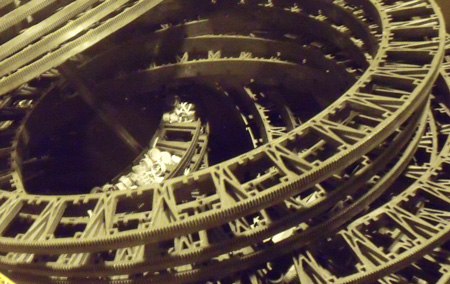

MIXED ENGINEERED INJECTION MOLD RESINS

Material: Mixed Engineered Resins Color: Mixed Colors (see pictures below) State: Parts in Gaylord boxes Quantity: 80,000 lbs per month - ongoing Location: Currently in Haw River, NC, Possible origination direct pickup. Specs: Call for details |